|

This is what we'll be

starting with. George sent this up and asked if we could duplicate it,

just with the sizes and offsets that would work for us. We think they

are old Divco Milk Truck wheels. When it comes to parts like this,

we've always relied on Mike Fossbinder and his crew at Fossbinder

Fabrications in Moline, Illinois. He has the equipment and know how to

make items like this happen. We will be making these a two piece wheel,

since the original was made this way. This will allow us to get a

perfect 90 degrees where the spokes meet the outer rim. We are going to

make 16's and 18's. We first drew up the 16's, then upsized everything

to do the 18's. This way, everything grows in proportion (rather than

just the spokes, etc). This should make for some really nice looking

wheels.

.

|

|

We started on the

centers first. Here's the beginnings - we have 4 pieces that will

eventually be the spoked centers.

|

|

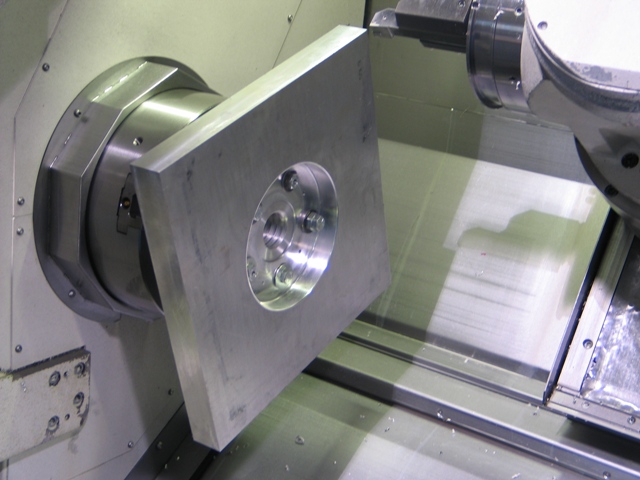

First area to be

machined is the bolt pattern and area for the centercap. This will

provide us an area to bolt down the piece when machining the spokes.

|

|

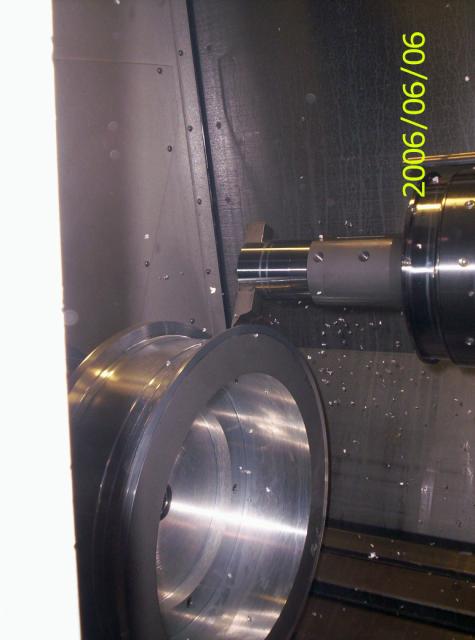

Now we need to make

it round (along with having the proper "dish"). This lathe will do

that in minutes.

|

|

Here's the finished

piece waiting to machine the

spokes. |

|

Once the program

was written to do the spokes, Mike thought it would smart to test on a

piece of wood. This way, we can do some refinement if needed without

costing us a piece of aluminum.

|

|

Here's the finished

piece of wood. We are now satisfied with the finished product and we

can move on to the aluminum.

|

|

Now on to the

aluminum. Because we wanted a really nice finish, this mill has to make

many passes before the spokes are complete. It's really pretty cool

watching this thing work. |

|

About half way there

(with the centers that is)! |

|

Because

we wanted the wheels to look as close to the originals as possible, we

went ahead and made our own hoops also. This way backspacing issues

were not a problem. This machine turned to these blocks into rims in

no time.

|

|

Here's the finished

pieces - you can see they are nicely proportioned. Next we need to make

the center caps, which will also be proportioned correctly from front to

back. |